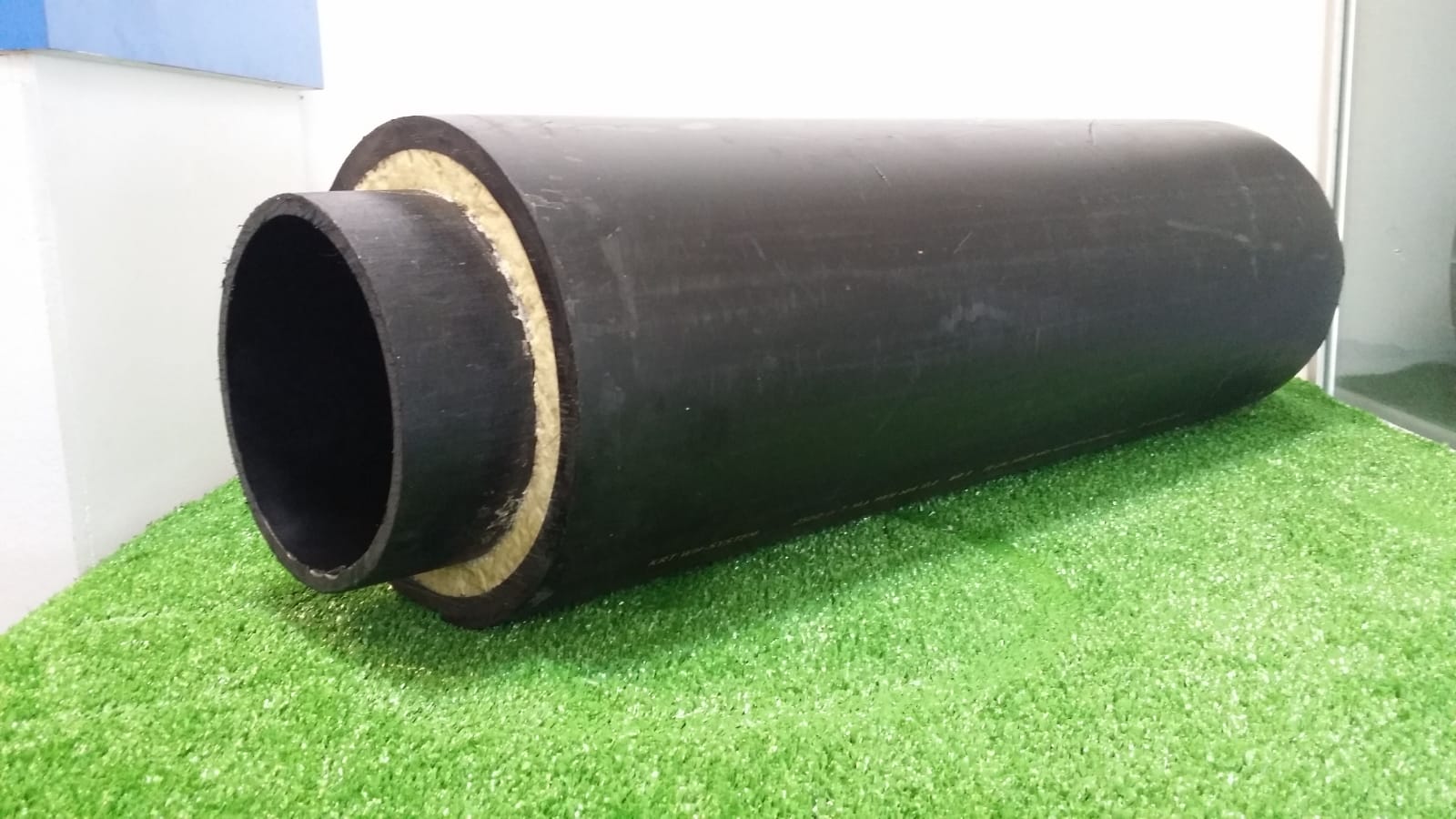

Polyurethane Pre-Insulation System

The Pre Insulated pipe are designed for district cooling which has become the preferred choice for energy and cost savings and promoting renewable energy.

The System consists the carrier pipe using polyethylene pipe and on the outside is a protective jacket of polyethylene (PE) or other material customize to client requirement, and an insulation layer made of polyurethane foam (PUR) filling the space between them.

- Longer life in comparison to steel pipes

- Weight lower than preinsulated steel pipes

- Excellent thermal insulation – low thermal conductivity coefficient over steel

- High smoothness of the surface resulting in lower resistance of flow.

- No corrosion of the inner and outer surfaces

- High chemical resistance to the vast majority of substances present in transported media