Simona PE100-RC

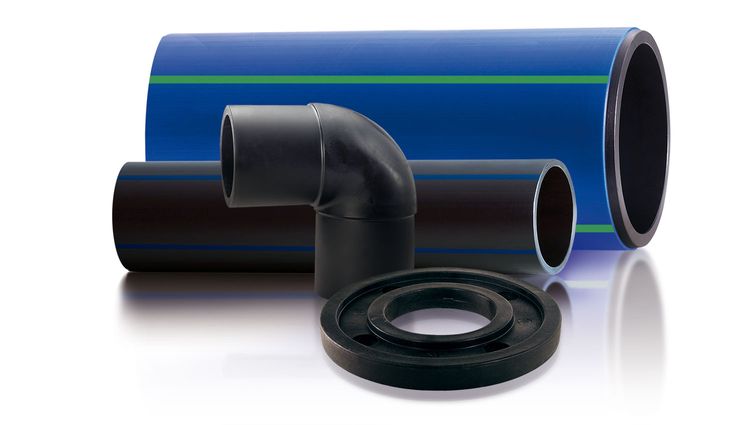

Pipes, injection moulded fittings, customised components and shafts made of PE100/PE100 RC ( PE100-RC ):

SIMONA offers a comprehensive product portfolio for reliable supply lines in the field of infrastructure applications.

- High stress crack resistance in sand-bed-free laying

- Tough pipes on account of high resistance to point loads (e.g. stones, fragments)

- Increased resistance to slow crack growth

- Long-term cost saving due to very good hydraulic properties attributable to smooth internal pipe surfaces, hence reduction of pressure losses over the entire service life

- Easy handling and increased safety in assembly due to lightweight, even if the design is complex

- Long maintenance intervals due to permanent corrosion resistance

- Excellent stability ensures the highest safety standards

- Outstanding UV resistance and weatherability enable outdoor use

- Exceptional ageing resistance

- No release of plastic particles into the drinking water